Home / Access Flooring / Products / Understructure

Access Flooring

Understructure

There are multiple options for access floor understructure that vary with the intended use, desired weight rating and level of accessibility. In some cases, seismic requirements will determine the sizing and bracing for understructure, and Longden can assist in this analysis. Custom understructure is also available for extended finish floor heights, extra low finished floor heights, high moisture environments, or any other requirements.

PosiLock™ System

- PosiLock design provides self-engagement and positioning on floor panels.

- Self-capturing fastener remains within the panel – will not get lost.

- Steel pedestal head provides optimum strength.

- Pedestal nut provides anti-vibration and locking features.

- Seismic force-resistant pedestals that limit or

eliminate the need for anchors or special bracing are available. - Typical floor heights from 6″-24″.

Bolted Stringer System

- Designed for computer rooms, data centers, industrial applications and heavy rolling load areas.

- Panels can be gravity held-in understructure for fast removal and replacement.

- Allows floors heights to be built higher than 24″.

- Stringers provide lateral resistance to heavy rolling loads and seismic loading.

- Seismic force-resistant pedestals are available that limit or eliminate the need for anchors or special bracing.

- Typical floor heights from 12″-36″.

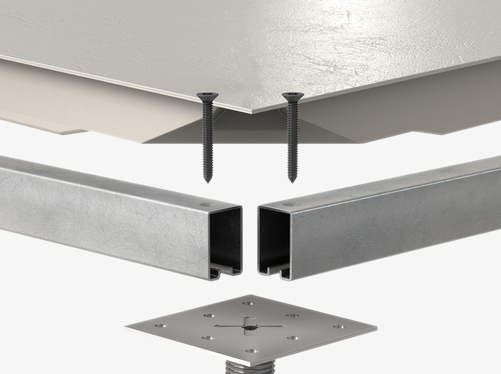

Heavy Duty Stringer System

- The heavy-duty stringer is designed for installations requiring additional design and rolling loads.

- Panels are gravity-held in understructure for fast removal and replacement.

- The galvanized construction reduces the risk of corrosion and prevents the formation of zinc whiskers.